A Guide to getting a Semi-Auto AKS-74U

How to cut and crown a SLR-104UR/AKS-74u SBR for cheap-ish lmao (2019 pricing) easily with some pretty basic tools.

Preface:

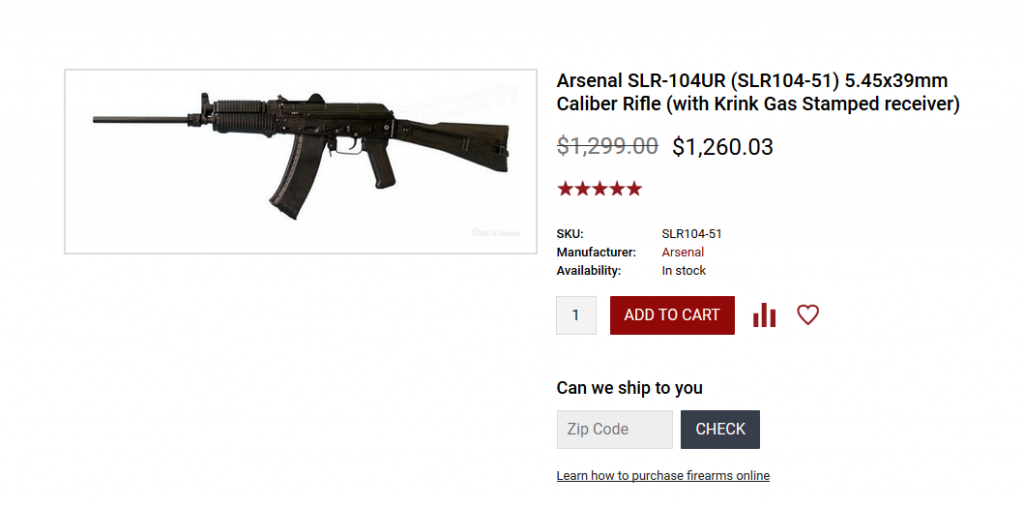

If you want an AKS-74u built by an Eastern European factory your best choice is buying a SLR-104ur. The most Economical way to do this is to buy the 16 inch version and chop it down. This is going to be a guide on how to do it.

Upfront cost is the most prohibiting factor for most people (why everything gotta cost money). But in the end you end up with a gucci rifle that few people own due to cost and unwillingness to file for the NFA Tax stamp. Total cost comes to roughly $1,600 after the $200 stamp, but before tools. If you already have the tools like the press and drill press this is pretty cheap.

A lot of this can be done with the Universal AK tool, the BFH if you want to cheap out. If you don’t want to attempt this I get it, it’s not for everyone, but this is really easy to do. It’s kinda basic, if you can put together an AR15 LPK you can do this. The crown I’m going for is going to be set up for suppressor use. I would go with an 11° target crown all the way across if you don’t plan on using a suppressor.

Tool List:

I’m only going to include the important tools in the list. Some of these aren’t strictly necessary, you could use a hammer instead of a Hydraulic Press. You do risk damaging your gun if you do use the hammer without knowing what you’re doing.

Harbor Frieght 12 ton hydraulic press

Robert Forbus barrel push back tool

4-1/2inch Angle grinder w/ cutoff wheel

Brownells .615″ Muzzle Radius Cutter

Universal AK Tool/BFH – 4lb dead blow hammer

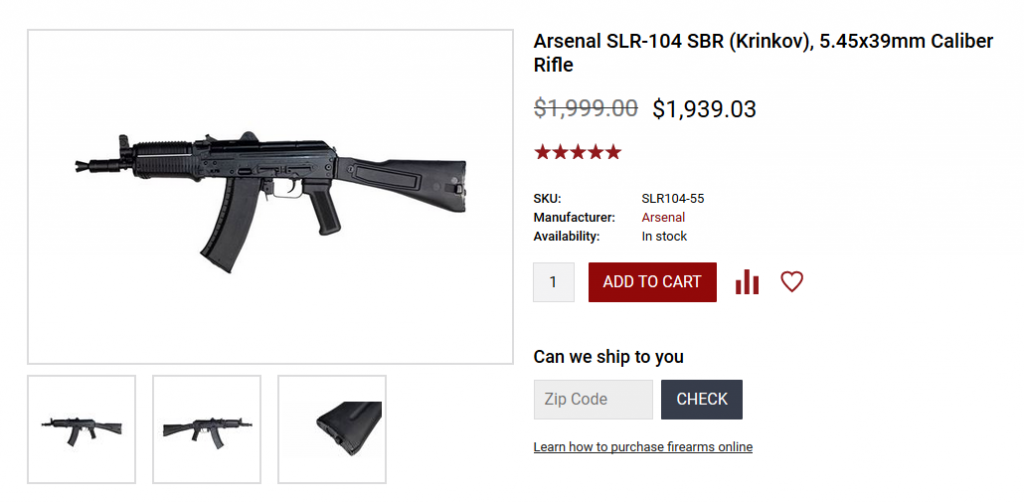

You could go other routes such as a kit build or a pre-cut, but with pre-cut you are paying $400+ more than this route as of today. Tula Kits are about $1,000 plus another $150 for the barrel, $30 for a flat, or $100+ for a 100%. Even then you come up pretty even with this.

The nice thing about the SLR is it has a side rail for optics which kits don’t usually come with. So you can get a Side Rail Mount from RS Regulate and put whatever your preferred RDS is on it. If you do get a Side Rail mount from them get the Rear Biased or Full Length mount, the forward biased will conflict with the dust cover rear sight. It’s more of a headache to go that route so this is the easiest option whilst still being very similar in price.

Why pay $1,900 when you can pay $1,260 lmao!

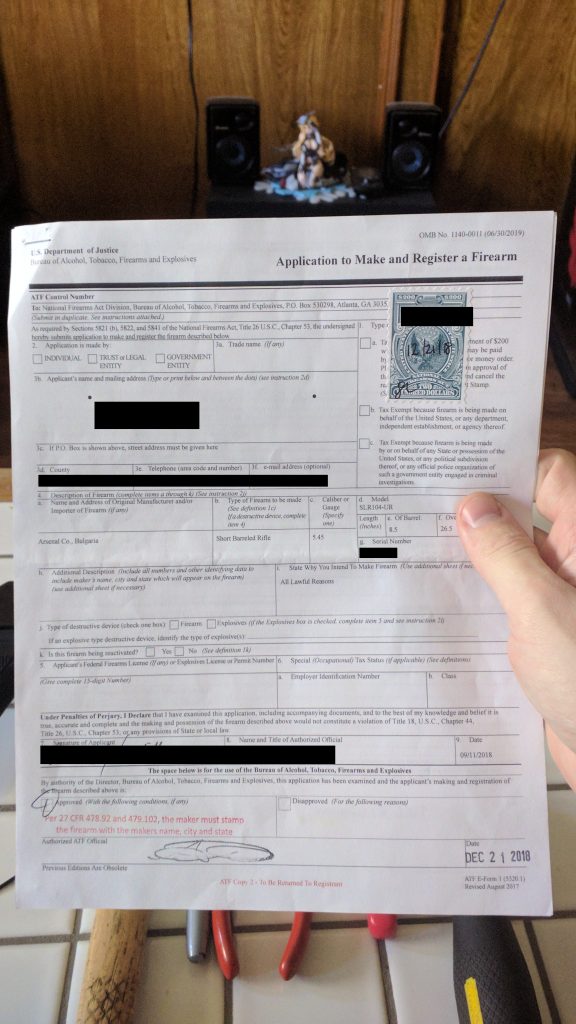

First things first before doing this you need to submit your Form 1 to the ATF. Make sure that SBR’s are legal in your jurisdiction. Many states restrict the ownership of NFA items and won’t allow you to own them. I’m in Texas so I can have whatever I want.

The pertinent information you need to submit a form is:

Manufacturer, type of firearm to be made, caliber, model, barrel length, overall length, and serial number.

In my case it’s Arsenal Co, Bulgaria, Short Barreled Rifle, SLR104-UR, 8.5inch, 26.5inch, Serial omitted for obvious reasons.

Once you get your stamp back you can manufacture your SBR. Since you are the manufacturer you will need to have the gun engraved with your name, city and state. In my case I put this on my trust so it has the trust name, city and state. You will need to have the caliber engraved on it if it isn’t already somewhere on the gun. In the case of an AR it being engraved on the Upper or Barrel itself is enough to satisfy the ATF, and almost every upper comes with the caliber written on it. In my case the caliber is already written on it.

Once this is all done you can start. By this point you’ll be 8+months into the process btw. The suffering is nearly over, friend.

Today is the day!

Got mine one day before the shutdown, Lucky!

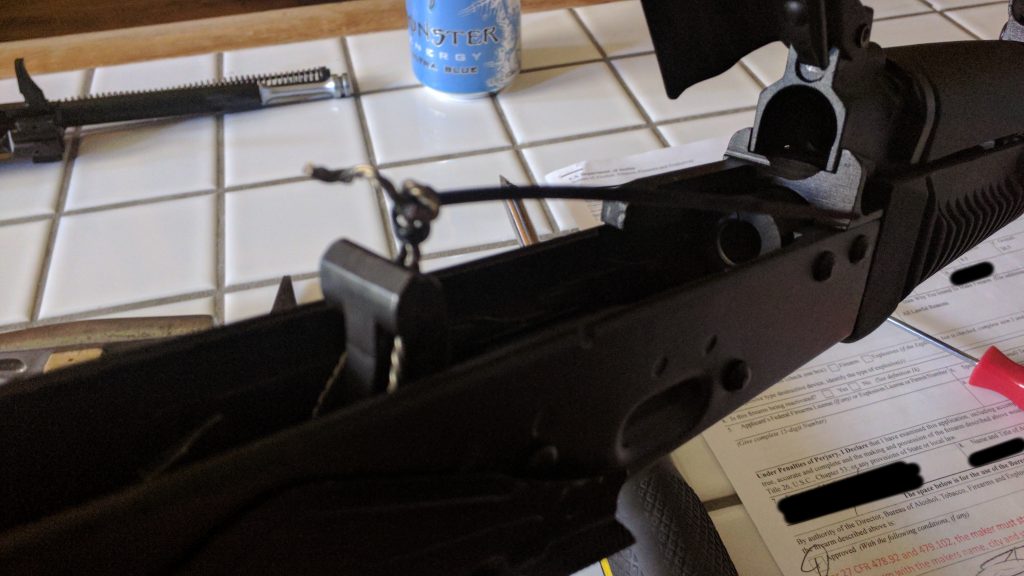

First is Disassembly!

All you really need are the tools pictured here, the pick is an underrated AK tool.

Tip: Zip tie the spring around the ears of the hammer like this after you pull them up with a pick.

Tip: buy an AK pin plate retainer, they’re like $5 and if you ever do this more than once you get sick of the paperclip pin retainers real fast.

Tip: Velcro the dust cover closed, it’s spring loaded and will pop open on you if you don’t. Might pinch your fingers if they’re in the wrong spot when it happens.

I highly recommend bagging everything up and setting it off to the side.

Before we can cut we need to mark where to cut. I do this before removing the gas block front sight. This step is necessary and we’ll come back to it later.

Punch out the pins holding on the gas block front sight.

Bag these pins with rest of the parts so you don’t lose them. These are easy to lose and the only parts on an AK I’ve ever lost.

Easy so far? Here comes the hard part.

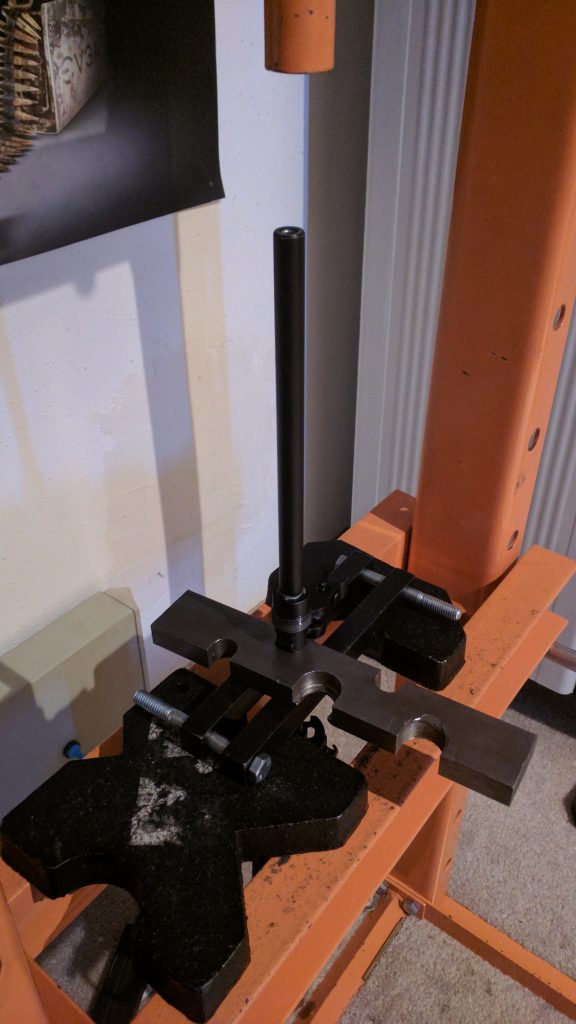

Set up your press like this.

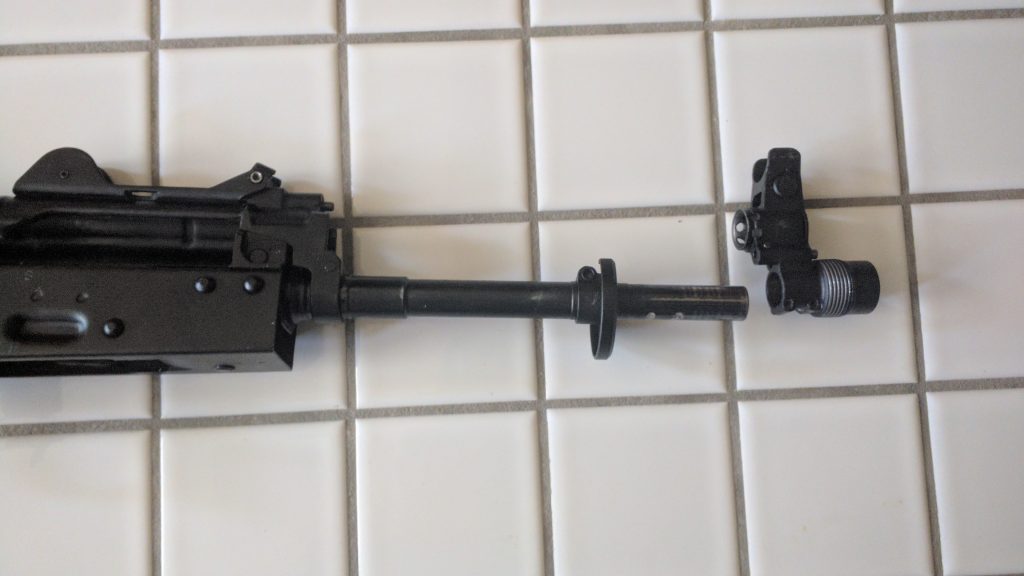

Press off the gas block front sight with the hydraulic press and press plate, no need to protect the muzzle because it’s going to be cut off anyway, normally I’d put some pennies on it to protect it.

🦀🦀🦀🦀🦀 GAS BLOCK FRONT SIGHT IS GONE 🦀🦀🦀🦀🦀

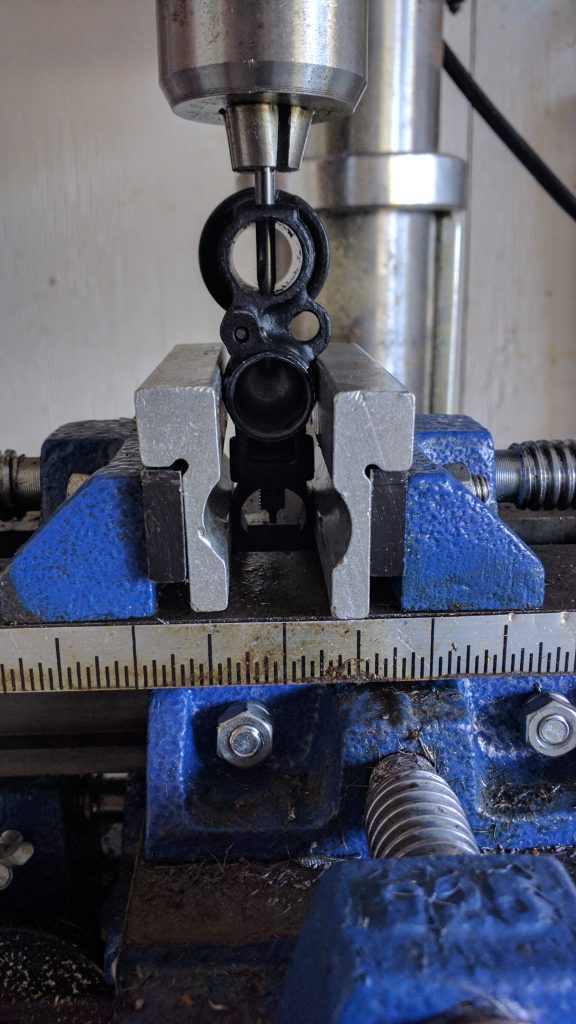

So we need to check if there’s a restrictor in the gas block. You can use a paper clip to check (pictured). We need to drill it out with a 5/32nd or 4mm drill bit. It’s pressed in and impossible to get out without drilling. I would highly recommend the drill press for this step. If you look in there with a flashlight it looks like a steel doughnut pressed deep in there. Impossible to get on camera.

Yup it’s in there and we gotta get it out.

Now that the Gas Block Front Sight is removed we can prepare it to be put back on the barrel, So originally these had an Open gas port meant to be used with the barrel cut down. People decided it would be a good idea to buy these rifles and shoot them without cutting down the barrel. Naturally this would damage the gun from being way over gassed so Arsenal started putting restrictors in the gas block to be able to fire with the 16″ barrel.

Retards ruin everything. Thank the dumbasses who thought it would be a good idea to fire their rifles before getting their stamps back for this needless step.

Drilled through, the restrictor is gone!

Now that we are marked with the gas block front sight done we can finally cut the barrel.

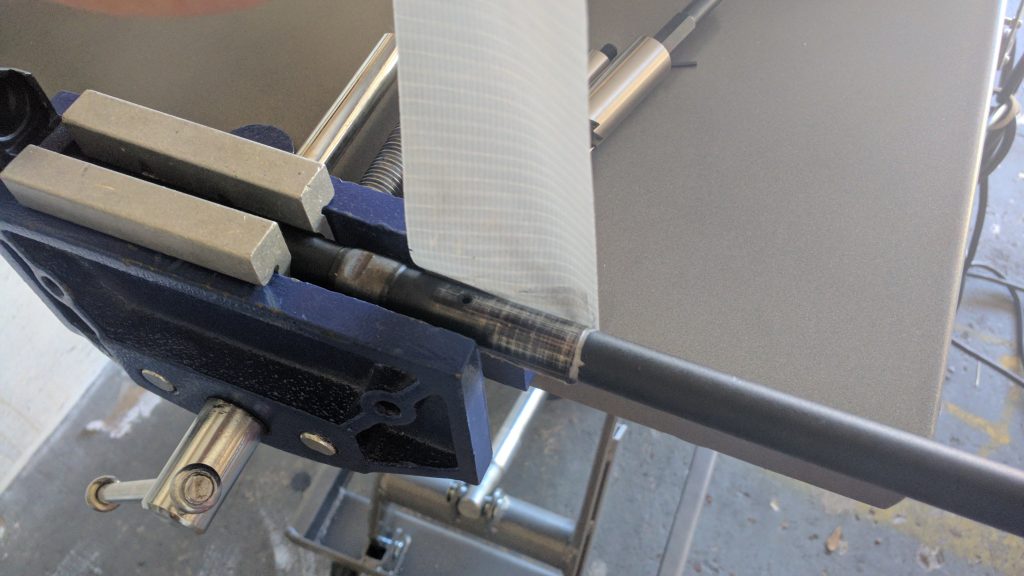

TIP: When you cut the barrel I highly recommend putting the barrel horizontal in the vise

When working with power tools, always remember PPE!

I would recommend putting some tape on the barrel, I used duct tape, but it kinda melted to be the barrel while I was cutting it. It came off with Acetone so go with masking tape.

It’s come to the Triarii!

Finally it is time to cut the barrel!

TIP: I cut the barrel long, and grind to nearly the final length with the grinding wheel on the angle grinder. Grind it to about 1.5mm, then use the facing tool for final length. I still leave it long by about 1mm. If you do it flush it becomes impossible to repair a crown. You’ll see later what I mean. I didn’t take pictures but I took off the cutoff wheel and put on the grinding wheel to get close to final dimensions for the crowning tool.

Now that it is cut, we need a crown. 11° would probably be better but I don’t know that much about crowns. I leave that sort of autism to the people who are trying to get sub-moa out of their bench guns. This is an SBR and we’re not going for sub-moa groups. I’m doing a 45° target crown, with a 90° face. A 90° face on the crown is better for the PBS-1 suppressor I have so that’s what I’m going to do. The PBS-1 on the inside interfaces with the face of the crown. I used the Brownells .615″ muzzle radius cutter on the outside edge.

You don’t need to go too deep with the 45° crowning tool, the objective of the crowning tool is a uniform surface for the bullet to leave the lands and grooves. It doesn’t take much to accomplish this. This might even be too deep. It should be fine. It doesn’t hurt anything if you go too far. I also used the Brownells .615″ Muzzle Radius Cutter to smooth the outside edge.

TIP: I highly recommend putting the barrel in the vise vertically so that you don’t get lateral movement on the crowning tool

Now that the barrel crown is done and the restrictor is drilled out we’re almost done. Now this is just reassembly.

WARNING: DO NOT FORGET TO PUT ON THE HANDGUARD RETAINER, If you forget you will have to press off the gas block front sight and try again!

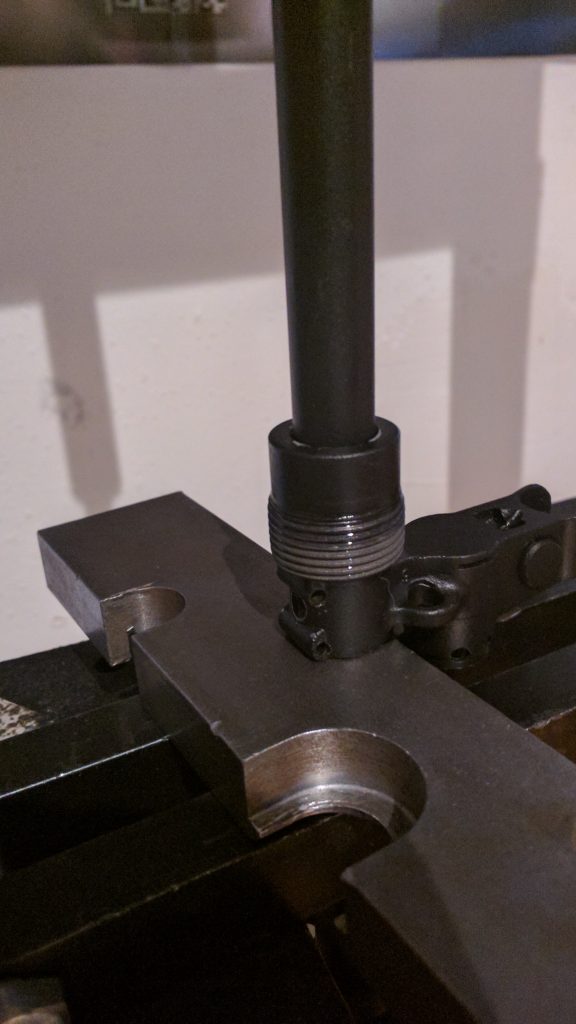

Now to press on the gas block front sight. I highly recommend getting the Robert Forbus tools for this part, you can use a 4lb dead blow hammer from Harbor Freight for this part entirely, but I don’t recommend it. You might need to use the BFH to correct the cant if there is any, but I lined it on my first try. You can always just press it on and off until it lines up too.

Tip: the Robert Forbus tool in this position has zero chance of damaging the crown we worked so hard on

This is what it looks like with it pinned in place. I leave it slightly long so it can be re-crowned. With a muzzle device the likelihood of damaging the crown is zero, but I am kinda stuck with this rifle. Because of the stamp I can’t get rid of it easily, so I don’t mind dumping a ton of rounds through it. Leaving it long opens up the possibility of recrowning it once the crown gets “shot out”. All that means is that the lands and grooves wear at the ends of the barrel and this will lengthen the service life of the barrel. At least in theory. I probably won’t put the round count into this to actually take advantage of it. It’s lined up and the Robert Forbus tool did it’s job in protecting the crown.

With it lined up I press the pins back in. This is the AK builder trunnion support block I use as a support with a brass punch. I would recommend buying the AK builder Front Sight Gasblock support.

Now for reassembly. Instead of using the thread protector that came with it, you’ll have to get a muzzle device, I recommend the PBS-1 Suppressor, or 4 piece Bulgarian Flash Hider, and if you wanna throw fireballs the AKS-74u Muzzle Booster.

Reassembled! The arsenal finish is shit and scratches easily, so I used a sharpie to correct any scratches I got from goofing.

Two Kalashnikov!

If you followed along, now you have a semi-auto AKS-74u. In my opinion it’s one of the best SBR’s that exist. Even 60gr Wolf tumbles like crazy, the loss in velocity doesn’t really matter for terminal ballistics. I keep a can of 1080rds of 7n6 around just for a rainy day, it’s sort of a meme. 7n6 is overrated IMO.

Next Guide I will be trying to make 7u1, it’s only meant to be used with AKS-74u and a Suppressor. With the stock folded it is the smallest you can get any SBR in an intermediate caliber without a really goofy modded AR folding stock. It’s an AK so it can still fire when folded where the AR can’t.

Everyone loves the classic look.

Since it’s a NFA item that you’ve basically married now (with marriage registration), it would be a good time to Cerakote.

Now for accessories.

There are plenty of furniture options, you can go with the classic wood handguards and triangle folder. You can get a recoil pad if you need extra length of pull, if you put an optic on it the SVD cheek riser works on the triangle folder. All those can be found on the AKfiles Marketplace. Arsenal makes a couple different stock sets you can buy on. You are on a 4.5mm rear pin for folding stocks. Zenit HGs from Legion or the AKSMU HG from Ironwood designs. There are even some US made stuff from Midwest Industries. Just about any Russian issued RDS will fit the AKS-74u out of the box. I particularly love the Kobra RDS on the AKS-74u. The possibilities are endless.